Optimized electrolyzer operability is a key differentiator when selecting a safe, reliable and efficient water electrolyzer for your project. That is why we design our water electrolyzers with operational convenience in mind.

In this blog post we discuss:

- How we organized the physical and remote access to our new HyGGe™ 100A water electrolyzer;

- The importance of integration, documentation and project management for optimized electrolyzer operability.

We look forward to hearing your thoughts and concerns regarding the operational convenience of water electrolyzers.

Optimized electrolyzer operability implies easy unit accessibility

The user-friendly design of our HyGGe™ 100A water electrolyzer allows for easy access and on-site as well as remote monitoring by authorized personnel.

Physical access to our electrolyzers

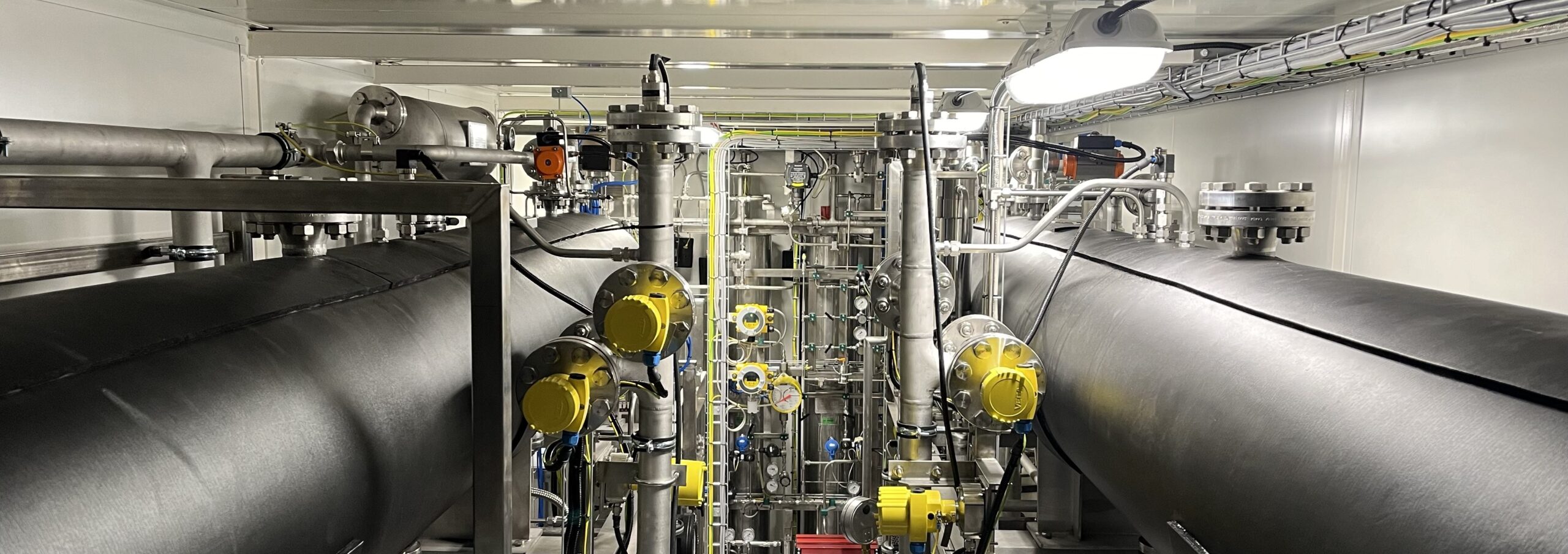

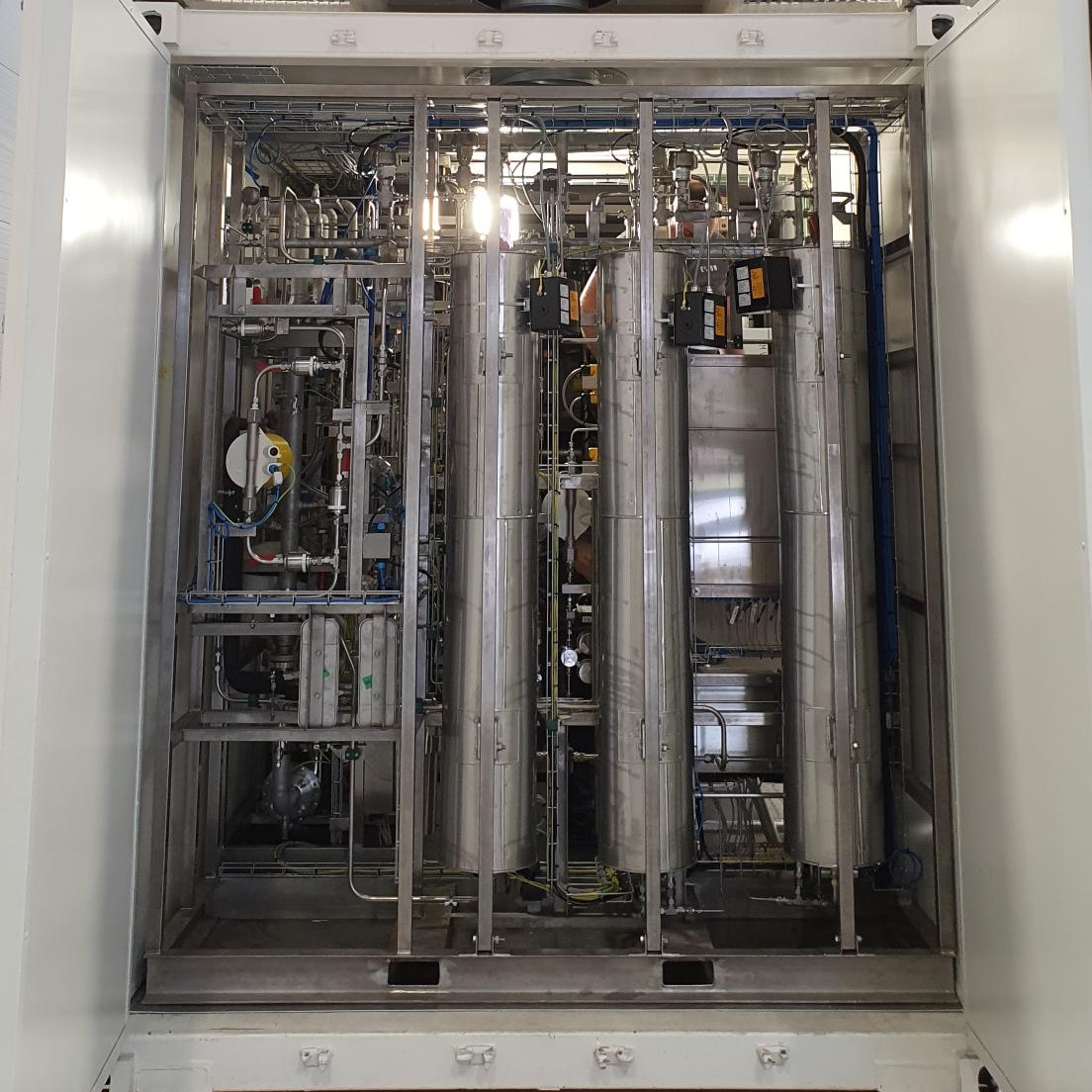

The HyGGe™ 100A water electrolyzer is housed in a robust 40ft HighCube container. Operators and service technicians can access the unit in various ways, according to their duties:

- The main doors at the front and rear end of the container give access to the Gas Purification Module and the Transformer.

- The doors in the side wall give access to the ATEX-zoned section and the general-purpose room.

- The low-height double doors on both side walls give access to the unit’s cell stacks in the Gas Generation Module.

- The ladder on top of the main unit gives access to the 20ft Rooftop Frame.

In addition, each individual section and skid inside the unit is optimized for easy and functional access.

Software access levels

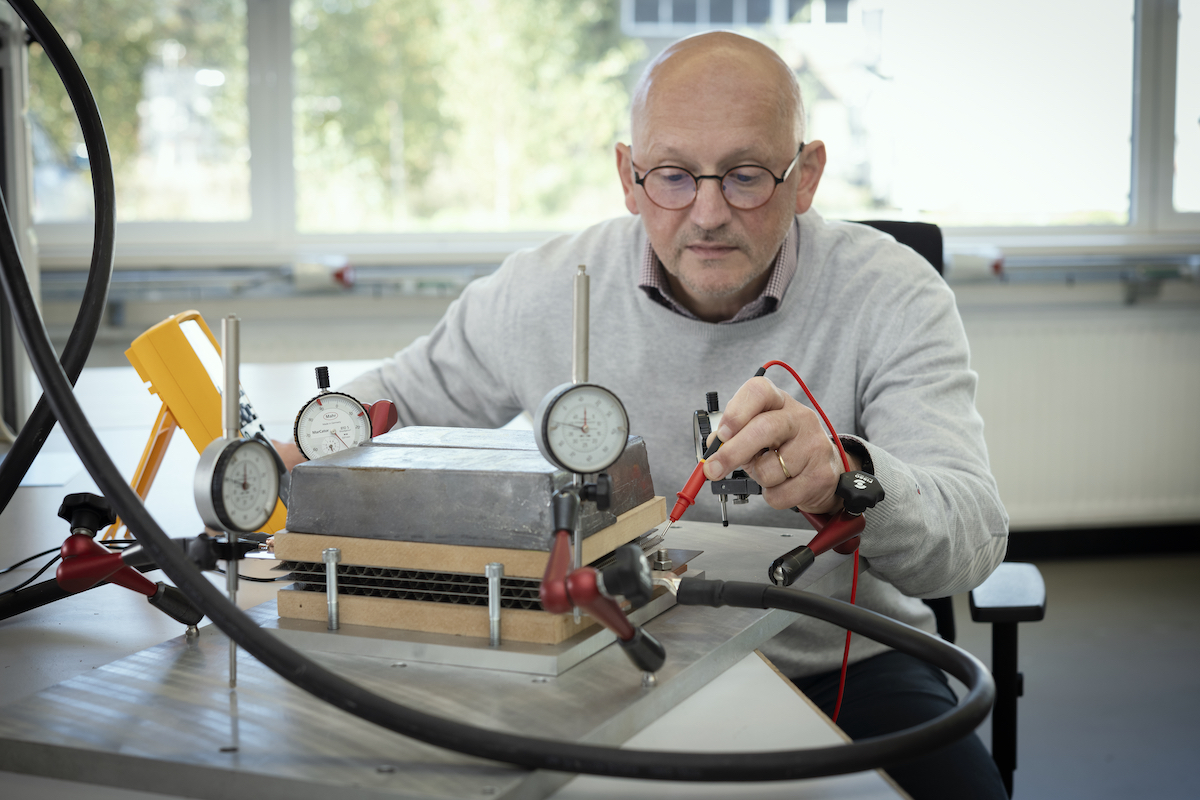

A detailed Process Control Narrative forms the foundation of our process control software, outlining every operational aspect of the hydrogen production process.

The HMI (Human Machine Interface ) in the General Purpose room enables clear monitoring of all relevant operating parameters. Operators can easily check and interpret operating conditions and safely start or stop operations. Restarting the unit after a safety trip requires the physical presence of an operator or designated technical deputy to ensure all safety conditions are met. Other system notifications can be reset remotely by a qualified engineer.

Access levels to the electrolyzer software vary based on the training and seniority of the person working with the unit:

- Operators can start and stop the unit and access all essential parameters. All data will be stored for reporting and analytics.

- Customer service teams have additional screens for advanced troubleshooting.

- Exion Hydrogen engineers can also change parameters remotely when this level of support is part of the service agreement with the customer.

Remote access to our water electrolyzer

When agreed upon and provided, a secured internet connection enables online support and remote interventions by Exion engineers and customer service teams. Our technical and operational customer support is set up to be as proactive as possible and as responsive as needed.

Operational data feedback allows us to build a knowledge database for each unit, monitoring parameter trends for proactive maintenance.

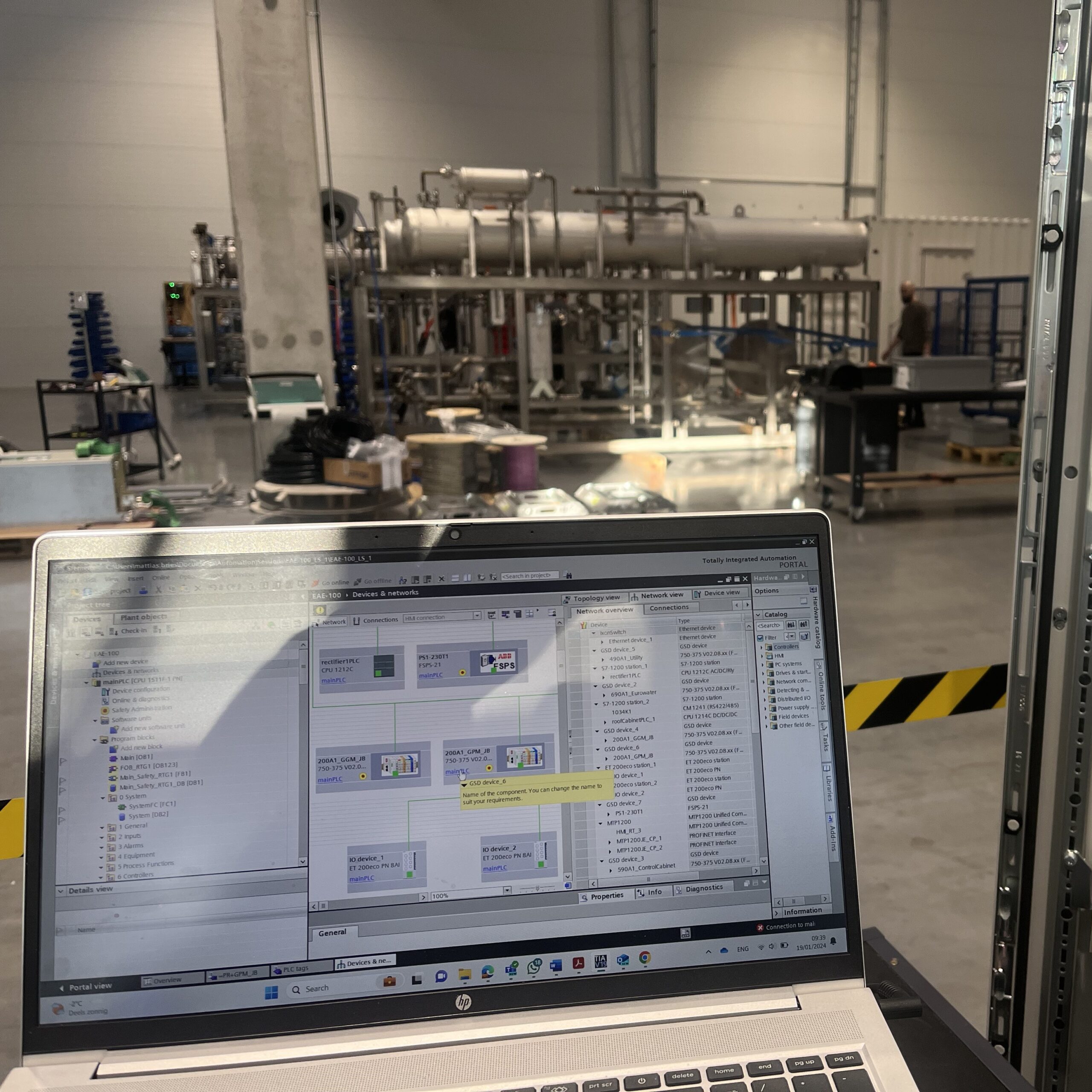

Integration with your Distributed Control System

The HyGGe™ 100A water electrolyzer can also be connected to your existing Distributed Control System (DCS/SCADA, etc.). Various connectivity protocols are supported to facilitate this integration.

This integration is reflected both in the unit’s HMI in the control room and in remote monitoring. This justifies a secured internet connection, enabling remote monitoring by both the customer and the OEM. This connectivity allows for proactive action, and it streamlines service interventions by Exion Hydrogen engineers and service teams.

Documentation and project management

The importance of a solid system monitoring interface and comprehensive product and operator documentation cannot be overrated. That’s why we make all help files and manuals readily accessible via the HMI. This ensures seamless communication with the Exion Hydrogen support personnel at any time.

Providing adequate support and guidance begins with the pre-installation and commissioning process, overseen by a dedicated Customer Success Manager. This key function streamlines all communications between your team and ours.

Beyond the HyGGeTM 100A unit

When it comes to water electrolyzers, convenience encompasses much more than delivering a safe, robust, and reliable unit. Operability must be functionally convenient for all designated technical personnel. Beyond that, clear status monitoring and reporting, and clear manuals and documentation, are all critically important.

That’s why we integrated all these aspects in the design of our new HyGGe™️ 100A water electrolyzer, and why we will keep integrating these aspects in all our future models.

We are eager to learn in the comments section below what your views and expectations are regarding the operational convenience of water electrolyzers.

Alternatively, please get in touch through sales@exionhydrogen.com or +32 14 91 99 19.