The main objective of our electrolyzers is to ensure safe, smooth and reliable hydrogen production throughout their lifespan. Through precise design and manufacturing processes that adhere to the highest standards, we guarantee these electrolyzers are exceptionally stable and durable from the outset.

To maintain optimal performance and minimize production interruptions, we provide premium electrolyzer maintenance services, including remote support, proactive preventive maintenance planning, rapid response times, and cost-effective emergency solutions.

This blog discusses:

- the importance of convenient and efficient electrolyzer maintenance;

- how our varying levels of maintenance support reflect our commitment to accountability.

We would love to hear your opinions and reflections on this topic.

Operational maintenance interface

Our water electrolyzers are designed for low maintenance, featuring easily accessible logs, test modes, and maintenance schedules via the Human Machine Interface (HMI). Separate logins and tools for operators and service technicians ensure appropriate access levels based on their roles and duties. For instance, operators will only have access to limited service functionality tasks such as temperature and pressure checks.

The HMI assistant

The HMI of our electrolyzers features a dedicated maintenance tab where service technicians can easily access maintenance logs, schedule overviews, calibration records, loop tests, and step-by-step instructions. In ‘safe mode,’ a maintenance assistant functionality helps with troubleshooting, serial tracking, and calibration tasks.

Both the HMI and the remote monitoring interface allow for routine status checks to ensure smooth operations. Additionally, the system offers HMI-integrated troubleshooting and test modes, simplifying and streamlining maintenance activities. This logically ties in with the availability of comprehensive on-screen maintenance documentation, including logs, schedules, and detailed procedures, to facilitate timely upkeep.

Safety front and center

Safety precautions are integral to our electrolyzer maintenance procedures and include multiple safeguards, such as safe states, inerting processes, and dedicated alarms designed to notify technicians of any safety concerns during maintenance.

Local electrolyzer maintenance support

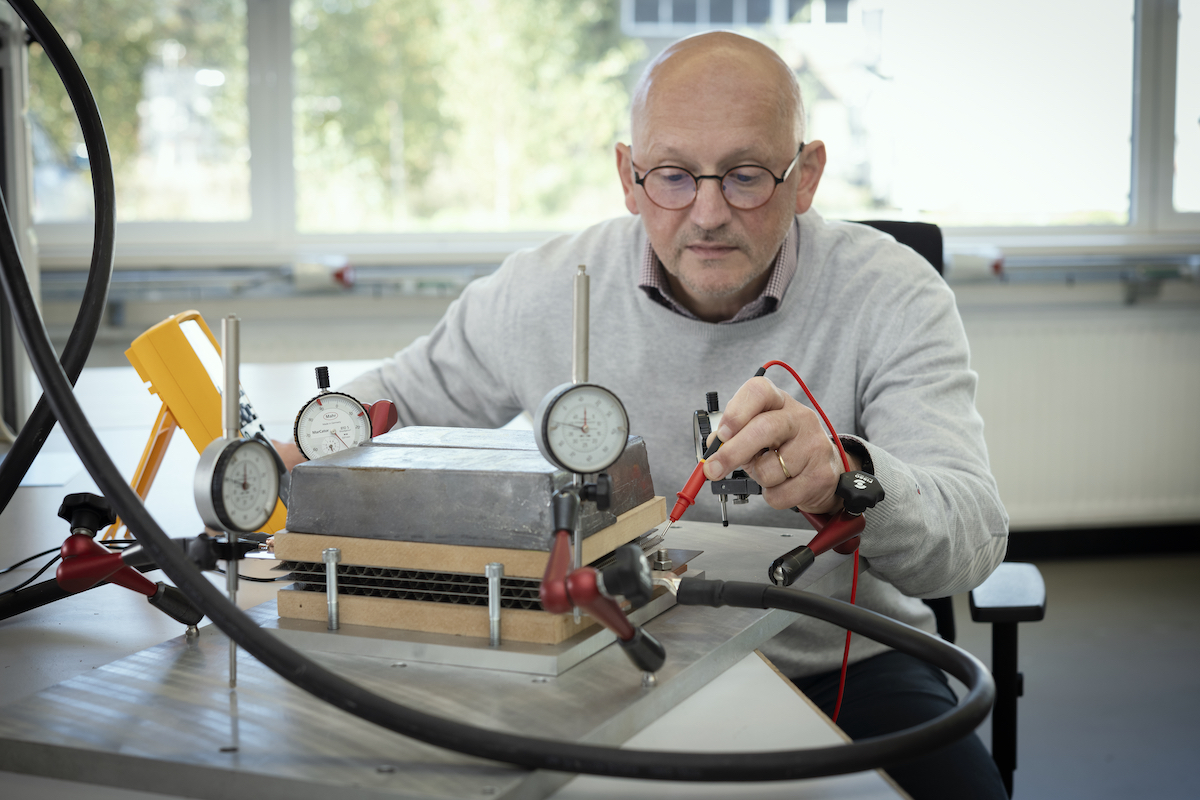

We always provide in-house testing (FAT), start-up and commissioning (SAT), and comprehensive operator training. This way, your operators are well-prepared to handle the daily electrolyzer maintenance tasks as outlined in our Service Manuals. Furthermore, our rigorous monitoring and follow-up of maintenance activities enable us to continuously improve our predictive maintenance capabilities, as per our Service Level Agreements.

Our most convenient agreement empowers your team to manage first- and second-line support independently. In this model, your operators serve as the first line of support, escalating any unresolved issues to their technical team. Additionally, we provide a comprehensive spare and wear parts package that covers 85% of service and maintenance needs, ensuring your electrolyzers remain up to date and operational.

For more complex issues, Exion Hydrogen Service Engineers can assist your technical team. This will resolve up to 95% of all questions and issues. In the rare case of unresolved issues, an on-site visit by an Exion Hydrogen engineer can be easily scheduled.

Uptime by design

Our electrolyzer maintenance contracts offer varying levels of support, with Exion Hydrogen Service team involvement covering in-house testing (FAT), start-up and commissioning (SAT), and on-site interventions, such as planned maintenance visits and optional installation support at the start of the project.

Customers with preventive maintenance contracts also benefit from included Remote Support. From filter replacements and sensor recalibrations to SIL loop testing and more, our planned maintenance scheduling adequately covers it all.

We take the uptime of your electrolyzers and your satisfaction very seriously. Depending on the Service Level Agreement you prefer, we can assist you with preventive maintenance, remote monitoring and support, or on-site support in case needed.

Do you have any questions, want to reach out, or want to work together?

Please get in touch through sales@exionhydrogen.com or +32 14 91 99 19.