Designing and producing water electrolyzers is a serious business, as is operating and maintaining them. Codes and standards for electrolyzer design are a reference baseline to ensure compliance in terms of safety and technical performance. Find out why this is key.

In this blog post we will share:

- how essentially important it is to embed all necessary safety measures in the design process as from the start;

- how crucial it is to understand and adhere to safety directives and standards to secure safe and efficient production and operation of electrolyzer.

We make sure that the compliance with codes and standards for electrolyzer design is front and centre in our design process. It simply is a prerequisite when it comes to the safe production, operation and maintenance of water electrolyzers.

We are curious to learn your perspective about standards for electrolyzer design in respect to safety and safety compliance.

Safety by design

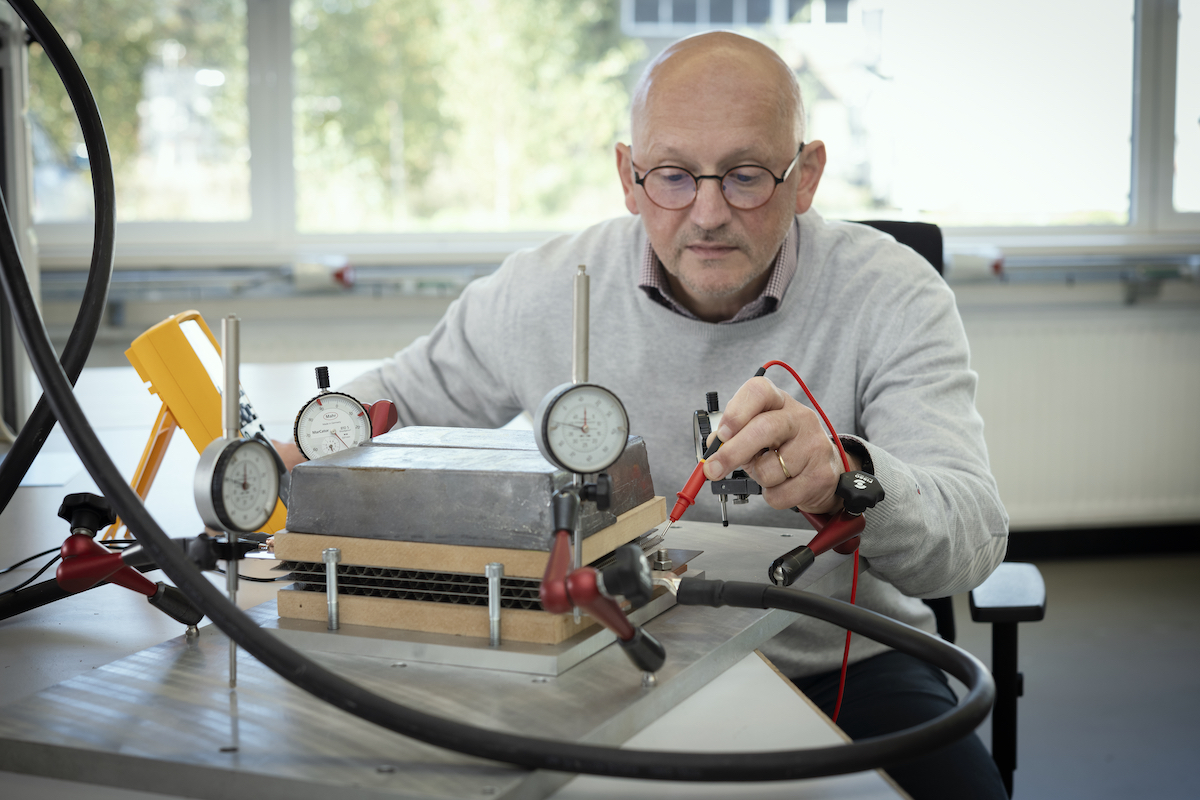

Securing safety through standards for electrolyzer design is about making safety measures and compliance intrinsic dimensions of the solution design process. From the early stages of designing our HyGGeTM 100A water electrolyzer that is exactly what we did.

First, the process drawings are scrutinized based on the HAZOP methodology (Hazard and Operability Study). Resulting safety attention points are then made subject to a LOPA analysis (Layer of Protection Analysis). Purpose of this exercise is to identify gaps for which Safety Instrumented Functions (SIF’s) need to be defined. The LOPA analysis also determines what Safety Integrity Level (SIL) the respective SIF’s need.

Only such a disciplined approach can yield the consistency and safety that we pursue. On this basis, we can enhance the unit’s overall performance and confidently ensure compliance with regulatory standards for electrolyzer design.

HAZOP as a means to an end

HAZOP (Hazard and Operability Study) is a method to identify and assess potential hazards and operational issues in industrial processes such as water electrolysis. It is an essential practice in managing industrial risks, ensuring safe and efficient operations, and fostering a culture of safety and continuous improvement. Guided by external, accredited companies, our R&D team analyses all processes to uncover deviations from normal operation, and the risks involved. On this basis, we implement preventive measures and define recommendations to further enhance safety.

Not without LOPA, SIF’s and SIL definitions

A Layer of Protection Analysis (LOPA) uncovers safety gaps and triggers the definition and implementation of Safety Instrumented Functions (SIF’s), for which it also determines a Safety Integrity Level.

Safety Integrity Level (SIL) is a measure to define the reliability of safety systems in industrial processes. It ranges from SIL 1 (least stringent) to SIL 4 (most stringent), indicating how likely a system will perform its safety functions under specified conditions. Based on IEC 61508 standards, SIL ensures safety systems are designed, implemented, and maintained to reduce the risk to an acceptable level. Its objective is to protect people, property, and the environment from hazardous events. We run sequential Functional Safety Assessments to document and reconfirm all safety objectives.

Standards for electrolyzer design

Understanding and adhering to safety directives and standards is crucial for the safe and efficient operation of electrolyzers. Our engineers vigorously interpret, cross-check and implement all relevant norms and standards, including:

- European Directives:

- ATEX Directive: ensures safe use of equipment in potentially explosive atmospheres;

- Pressure Equipment Directive (PED): governs the design, manufacture, and conformity assessments for safe use of pressure equipment;

- Machine Directive: consists of safety design principles, protective measures and user information to ensure the safety of machinery;

- Low Voltage Directive: aims to protect users from health and safety risks associated with electrical equipment;

- Eletromagnetic Compatibility Directive: ensures that electrical and electronic equipment does not generate, or is not affected by, electromagnetic interference.

- International Standards:

- ISO (International Organization for Standardization): sets international standards to ensure the quality, safety, and efficiency of products and systems;

- IEC (International Electrotechnical Commission): defines international standards for all electrical, electronic and related technologies;

- EN (European Norm): comprises harmonized technical specifications and criteria to ensure the quality, safety and interoperability of products and services across Europe;

- ASME (American Society of Mechanical Engineers): provides codes and standards for mechanical devices, promoting safety and reliability.

Safety beyond the necessary

We not only pursue legal conformity but also ensure enhanced safety, performance, and environmental sustainability. In the process, verification and certification by third parties validates that our electrolyzers meet high safety and performance standards. This is how we secure and support the safe transition to green hydrogen production.

Do you have any questions, want to reach out, or want to work together?

Please get in touch through sales@exionhydrogen.com or +32 14 91 99 19.